SECO/WARWICK` solutions for heat treatment of metals

At SECO/WARWICK we approach each project individually – a client often looks for a solution that requires cooperation between different segments. We get to know the client’s needs and together with experienced experts, we choose the best technology.

Industries: solutions for the automotive, aerospace, energy, medical or military industries. In a nutshell, for every industry. Specialists from SECO/WARWICK work together to find solutions that are right for your company.

Unique features: energy-saving and environment-friendly equipment, access to new solutions and technologies defined by us, modern data control and analysis systems, professional and 24/7 professional services available in every part of the world.

Technologies: delivering the best results, as our partner you have access to knowledge, experience, technology and specialists in the field of engineering and science, who are looking for further solutions.

Scope: standard and dedicated solutions, delivery of equipment with technology and associated devices, assembly and startup, service support, technical and technological training, tests and research in industrial and laboratory conditions, analyzes and simulations.

SECO/WARWICK solutions also include: fire resistance tests furnaces, vacuum equipment, heat treatment equipment, chambers for precision tests, thermal processing systems, production lines for heating car windshields and their formation, and an individual solution prepared for your company, allowing you to gain an advantage over the competition.

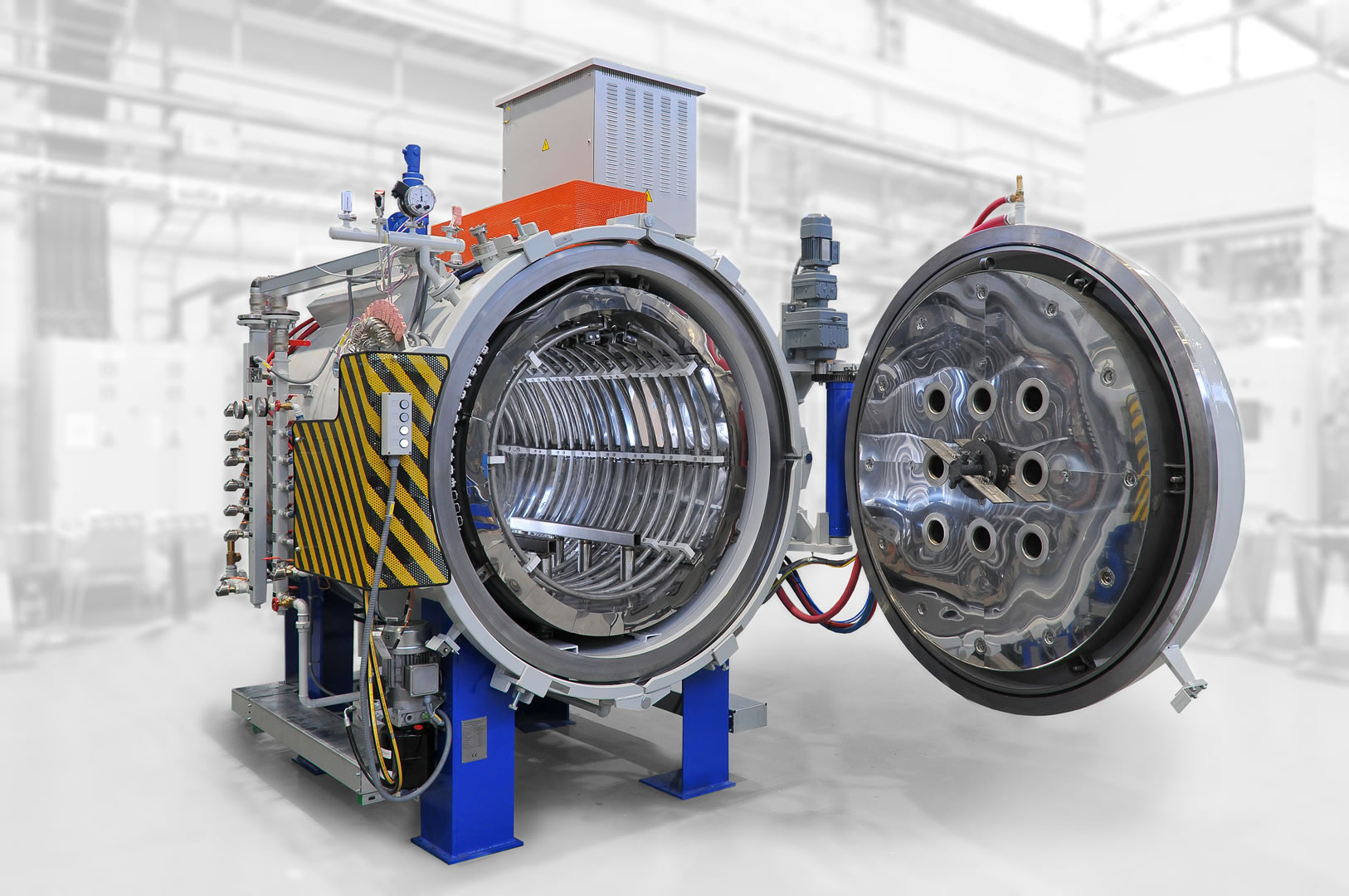

VACUUM HEAT TREATMENT FURNACE SYSTEMS

Vacuum heat treatment technologies and equipment

Modern, precise, energy efficient and ecological vacuum heat treatment equipment with guaranteed technology. SECO/WARWICK’s experience in developing these solutions dates back to the 70s of the twentieth century, when vacuum-based heat treatment technologies emerged in the aerospace, automotive, defense, metallurgical, medical, nuclear, and utility industries. Over the last 25 years, the company’s dynamic development has delivered more than 700 complete installations in more than 40 countries, and many of the technologies delivered have become a challenge to traditional technologies.

Technologies: annealing, solution heat treatment, brazing, sintering, gas and oil hardening (HPGQ), FineCarb® and PreNitLPC carburizing (LPC), nitriding and other special technological processes.

Industries: aerospace, energy, defense, medical, machine, automotive, tool, hardening plants.

Unique features: dynamic and efficient heating system, precise temperature control, excellent temperature distribution in the working space, efficient and uniform cooling, compact and modular design.

Parameters: single-, double- and multi-chamber batch and bulk furnaces, in horizontal and vertical configuration, low-, medium- and high vacuum, radiant and convection heating, low- and high pressure (HPGQ) gas cooling in pressure up to 25 Bar or hardening in oil, full automation, computer control system. Compliance with world safety and quality assurance standards.

VACUUM MELTING FURNACE SYSTEMS

Vacuum melting technologies and equipment

Vacuum metallurgical equipment is manufactured in our facilities in the United States, Poland and China, which are the regions with the highest demand for high-melting and foundry technologies. Since 2006, as a result of strategic acquisition of Retech, we offer our customers worldwide a comprehensive solution in the field of melting furnaces and heat treatment furnaces. Our customers have become the beneficiaries of synergies resulting from the merger of companies.

Technologies: equiax casting, directional solidified casting, single crystal casting and electrodes, titanium scrap consolidation, metal melting and refining, metal powders, amorphous continuous casting, plasma welding, hazardous and radioactive waste utilization.

Industries: aerospace, energy, defense, powder metallurgy, medical, automotive and nuclear.

Unique features: high performance, repeatability, process automation, modern control system with monitoring of each parameter, precise feed system.

Processed materials: titanium and its alloys, tantalum, tungsten, niobium, zirconium, silicon, copper, precious metals, nickel, cobalt alloys and others.

For additional information, visit www.retechsystemsllc.com

.jpg)

.jpg)