Aimtek manufactures a complete line of Brazing Filler Metals (BFM) in a variety of forms, such as wire, foil, strip, washers, discs, paste, preforms, powder, ribbon and rings.

Precision Spooled Wire

Aimtek’s precision level layer wound welding and brazing alloys are available in a variety of spool and reel sizes. Typical spool sizes range from 12” diameter down to 4” diameter, but custom spool and reel sizes are also available. Spool materials include plastic, fiberboard, and metal.

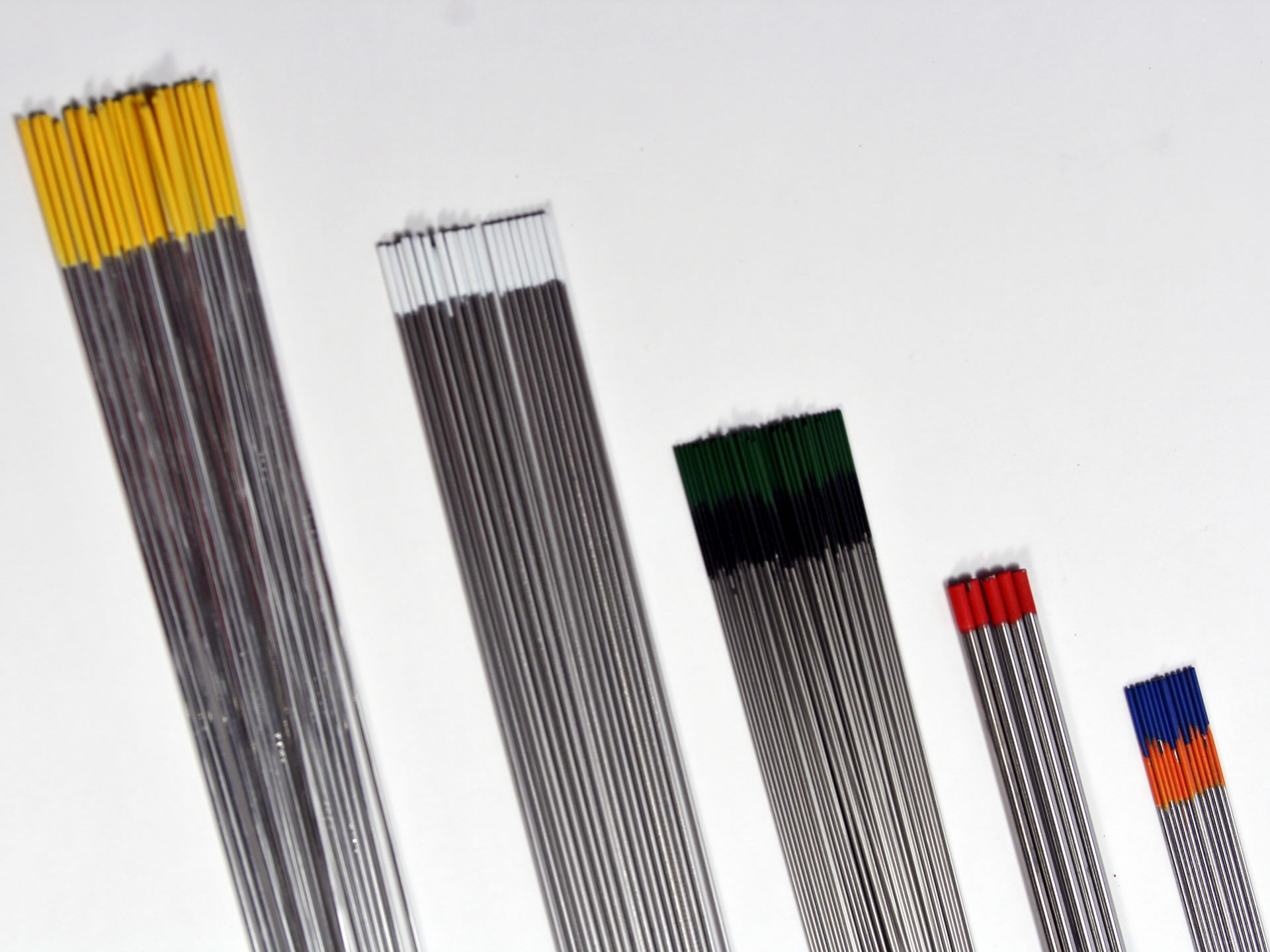

Cut Length Wire

Aimtek’s precision wire straightening and cutting capabilities enable wire to be cut to virtually any length and tolerance. Wire is cleaned using ultrasonic, solvent, and mechanical based methods. Surface condition and cleanliness meet the strictest aerospace and industry standards.

Braze Powders and Paste

Many brazing alloys are available in powder and paste form. All powders are inert gas atomized and screened to particle sizes ranging from fine to coarse. Aimtek’s proprietary paste formulations and mixing processes provide smooth flowing product through a variety of cartridge and syringe dispensing equipment. Binders are chosen based on the brazing process, and will not leave behind a residue on the part.

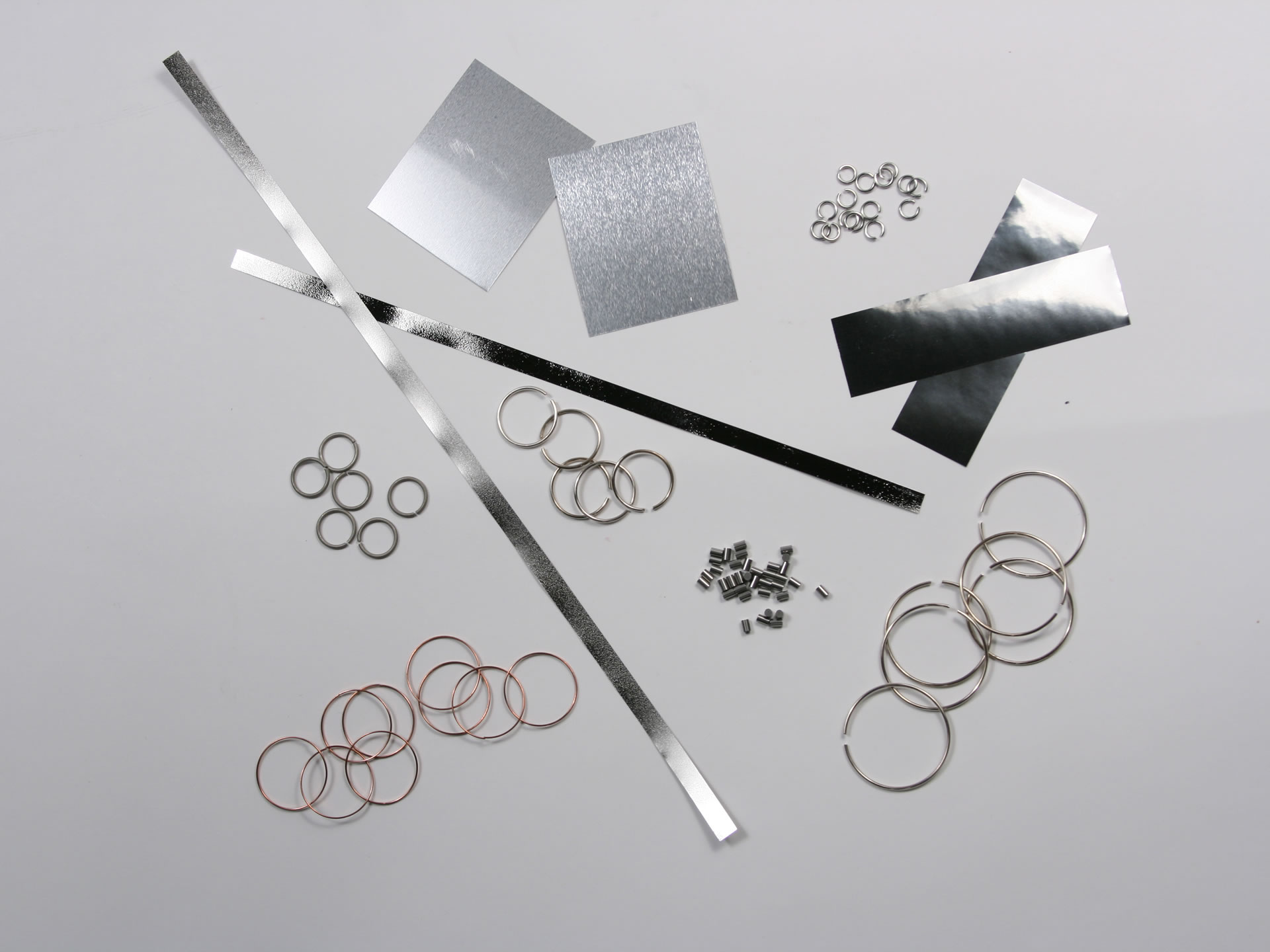

Braze Foil and Tape

Braze foils are manufactured using precision rolling and melt-spun processes. Custom slitting can produce widths as low as 0.020” to greater than 12”. Tapes are manufactured using the highest quality binders and adhesives, which are cleanly burned in the brazing process.

Braze Rings and Preforms

Brazing rings and preforms are manufactured to customer drawing requirements and can accommodate endless part configurations and brazing methods. Manufacturing processes include turning, stamping, laser, waterjet, and presintered performs (PSP’s). Our engineering department can help design a preform to improve your productivity and eliminate waste.

Flux and Brazing Aids

Aimtek stocks all major brands of flux, stop-off compounds, and chemical aids. Flux meets popular industry specifications such as AMS3410, AMS3411, AMS3417, PWA809, AWS A5.31, and O-F-499D. Stop-off compounds are formulated for all types of brazing methods and base materials.

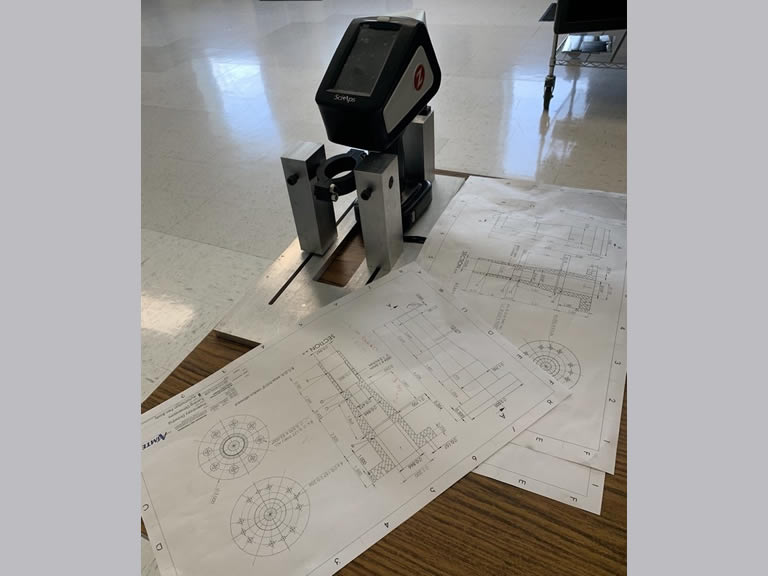

Test Coupons

Aimtek supplies test coupons in many forms for welding and thermal spray process qualification. Test pieces are manufactured to tight tolerances from bar, sheet, and plate using precision machining methods, which may include laser and CNC.

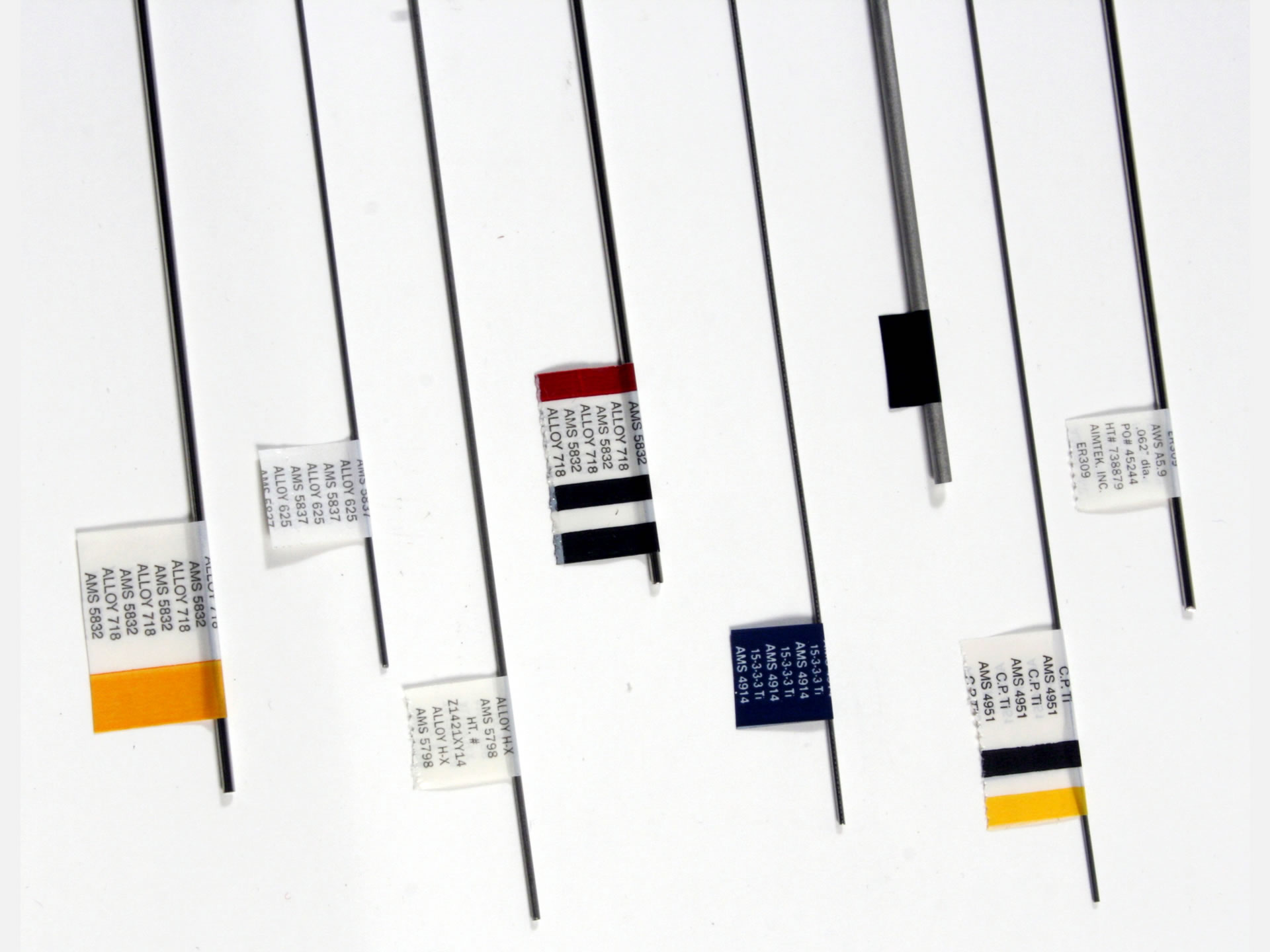

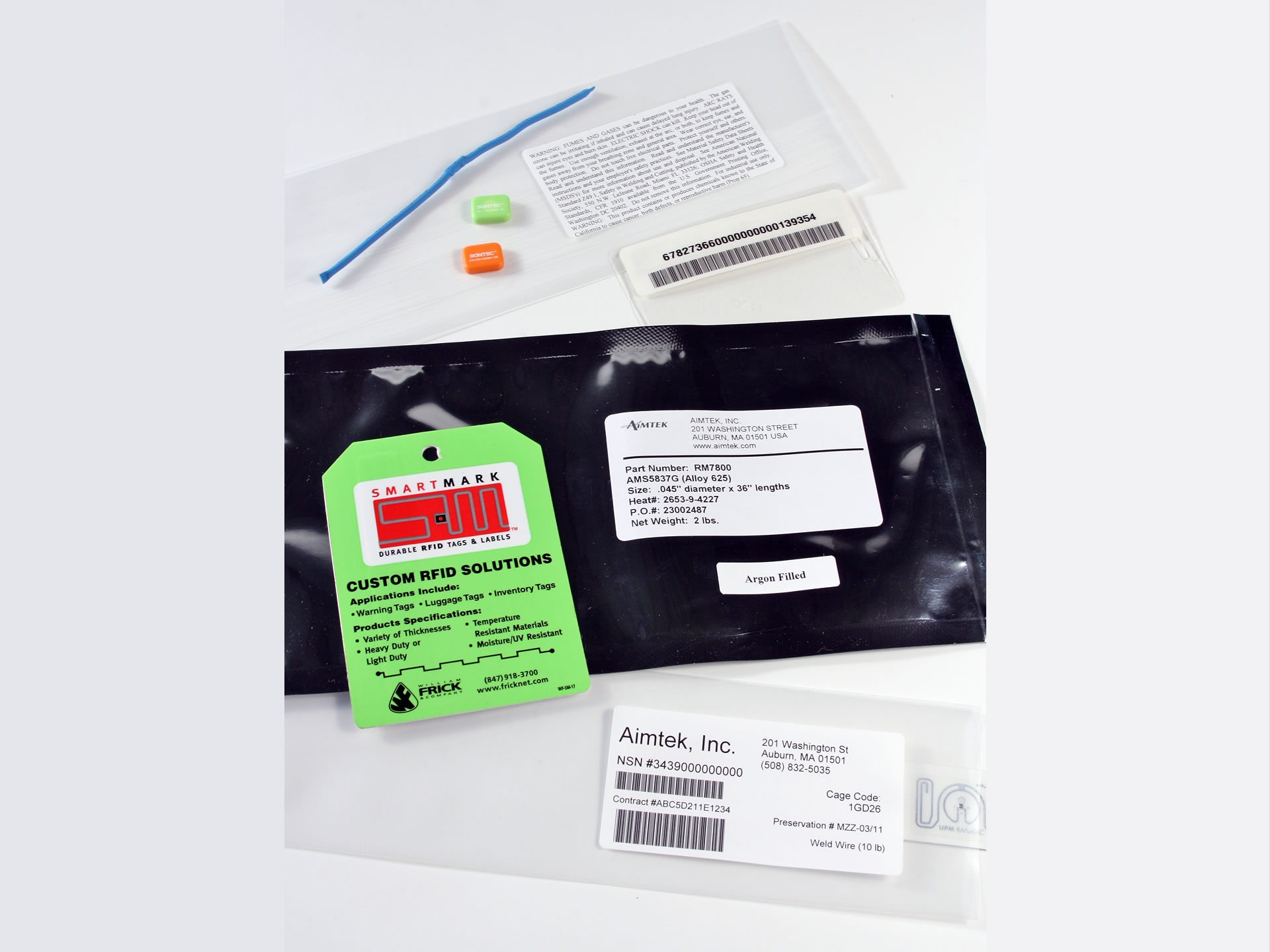

Custom Labeling, Identification, and Packaging

Ensure product integrity by utilizing Aimtek’s custom identification and packaging solutions. Welding and brazing alloys can be individually packaged and identified by many industry-approved methods, including flag tagging, color coding, bar coding, and RFID. Flag tag labels can be custom printed to include information such as lot and purchase order numbers. Color coding is performed using high quality painting methods and materials. Finished product is alloy-type tested using Acromag and other approved alloy verification methods. Packaging solutions include heavy thickness polyethylene, vapor-barrier materials and high-strength corrugated boxes. Argon purge and vacuum packaging is recommended for Titanium, high-purity, and corrosion-prone materials. All packaging and labeling is performed to customer specifications.

Value-Added Services:

- Vendor Managed Inventory (VMI)

- Parameter Development

- Application Support

- Laboratory Testing

- Engineering and Design

- Process Optimization

Engineering Department

Our engineers have many years of experience in the Metallurgical and Thermal Processing fields. Aimtek can assist our customers in developing brazing parameters, furnace conditions, surface preparation, and welding parameters. Consulting services are also available.