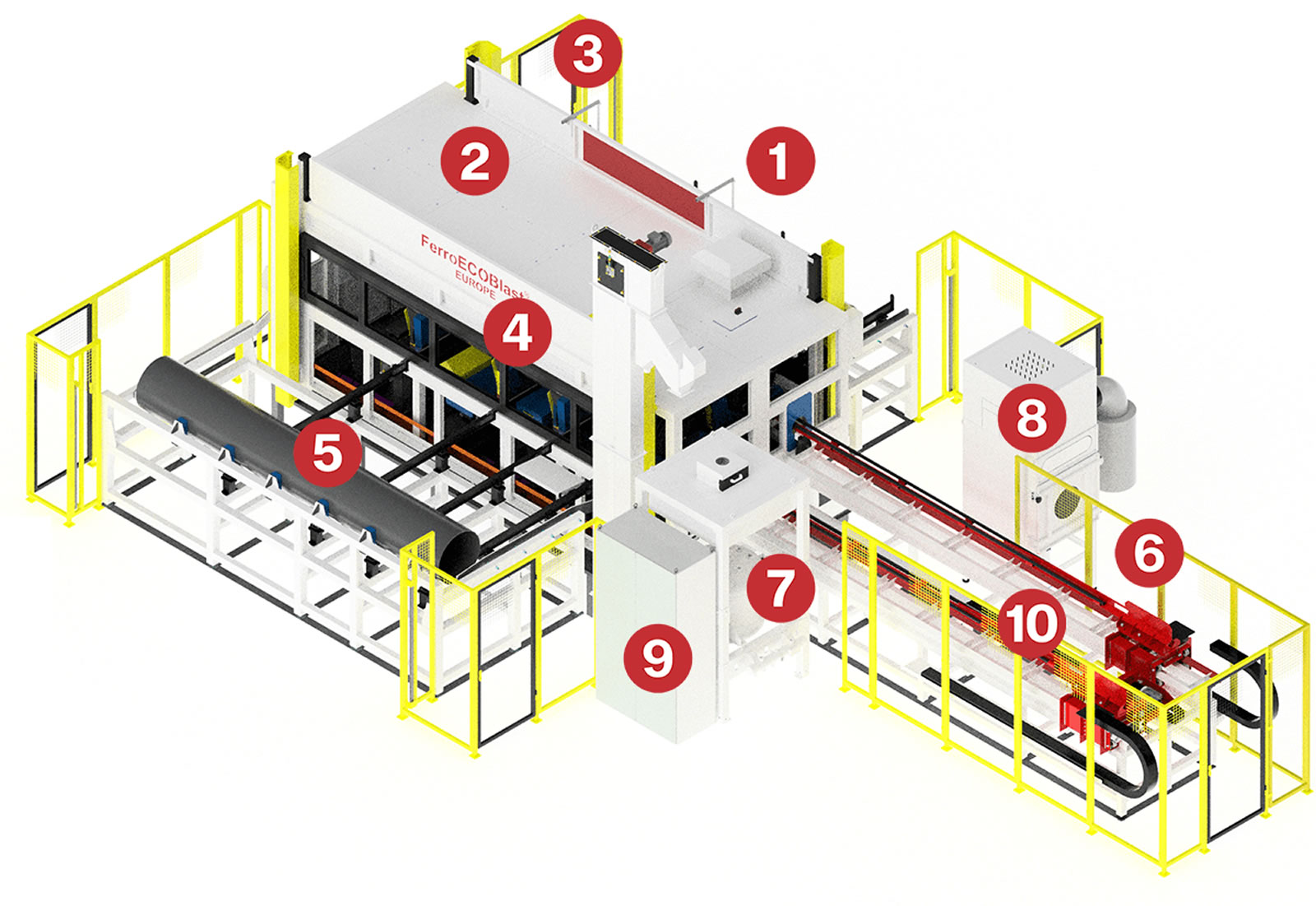

Pipe Inblast Duo ECO

Standard pipe inblast installations by FerroECOBlast® Europe are suitable for processing pipes with diameters ranging from 100 mm up to 700 mm and lengths ranging from 4.0 m or less and up to 12 m or more. Other dimensions and custom-built machines are also available on request.

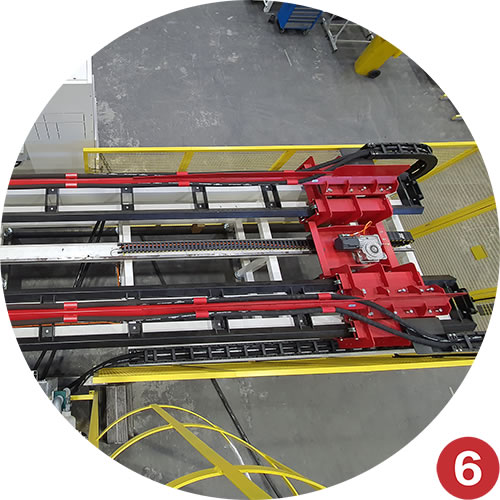

This unique solution delivers a fully automated and controlled blasting process, where constant quality, process repeatability and high productivity are ensured by setting a combination of optimal parameters for each pipe, such as pipe diameter and length, pipe rotation speed, sandblasting pressure, nozzle speed, blowing pressure, and more.

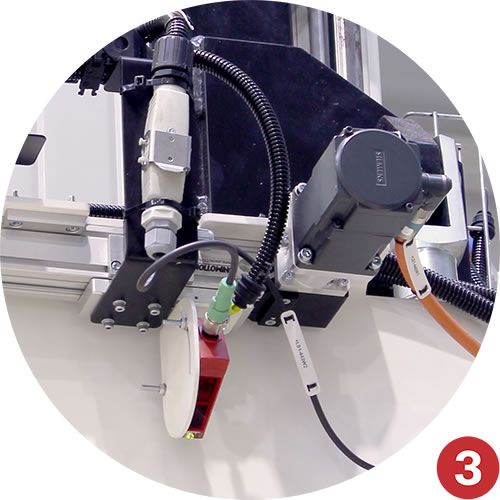

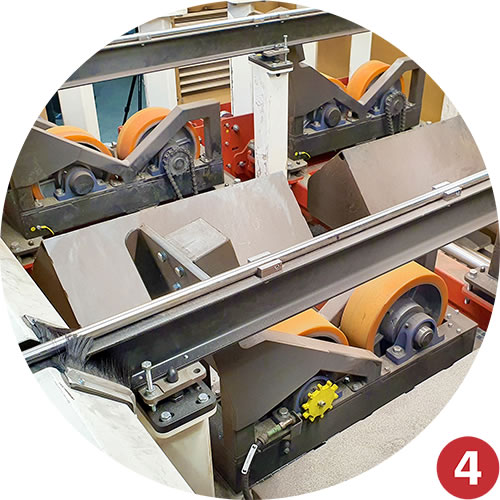

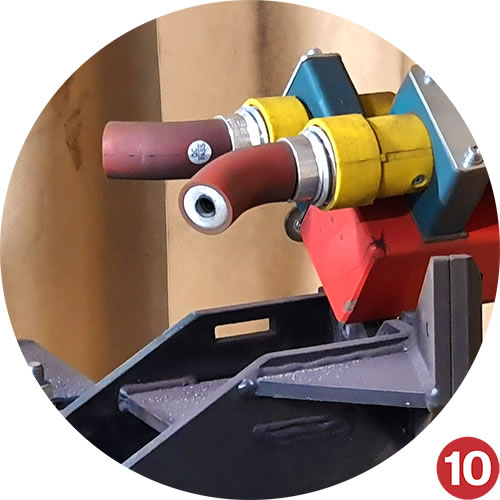

The inside surface of pipes is blasted using a custom-made lance movement blasting system. Abrasive stream covers the inside surface of pipes with the help of compressed air by using special designed types of nozzles. During this process, a set of two pipes are automatically positioned into enclosed chambers, ensuring the highest productivity. Blasting media in continuously and automatically collected from cabinets floor and recycled through the air separation unit, enabling only the good media to be filled back to the pressure blasting system. This product line presents unique solution on the market of oil and gas industry, with all combined features in a fully automated and high productivity FerroECOBlast® Europe inside blasting machines.

Key benefits of the installation

- In-line integration into new and existing installations

- Automatization – the system is completely automated and fully controlled from loading onwards. The automatic system offers 100% repeatability, runs 24/7, and maximizes the quality of end products

- Rigid blasting machine with additional wear protection solutions, safety and warning system

- High productivity – achieving the shortest cycle time and increasing operational capacities

- Flexibility and user-friendly operation

- Cost reduction – minimal manual input means substantial cost savings for the customer. Constant reuse of abrasive materials

- Environmentally friendly – replacing unhealthy chemical process, meets HSE standards

- Easy maintenance – machine is self-diagnosing (troubleshoot pop-ups) and designed for fast service operation, also allowing remote control access to our 24/7 service support