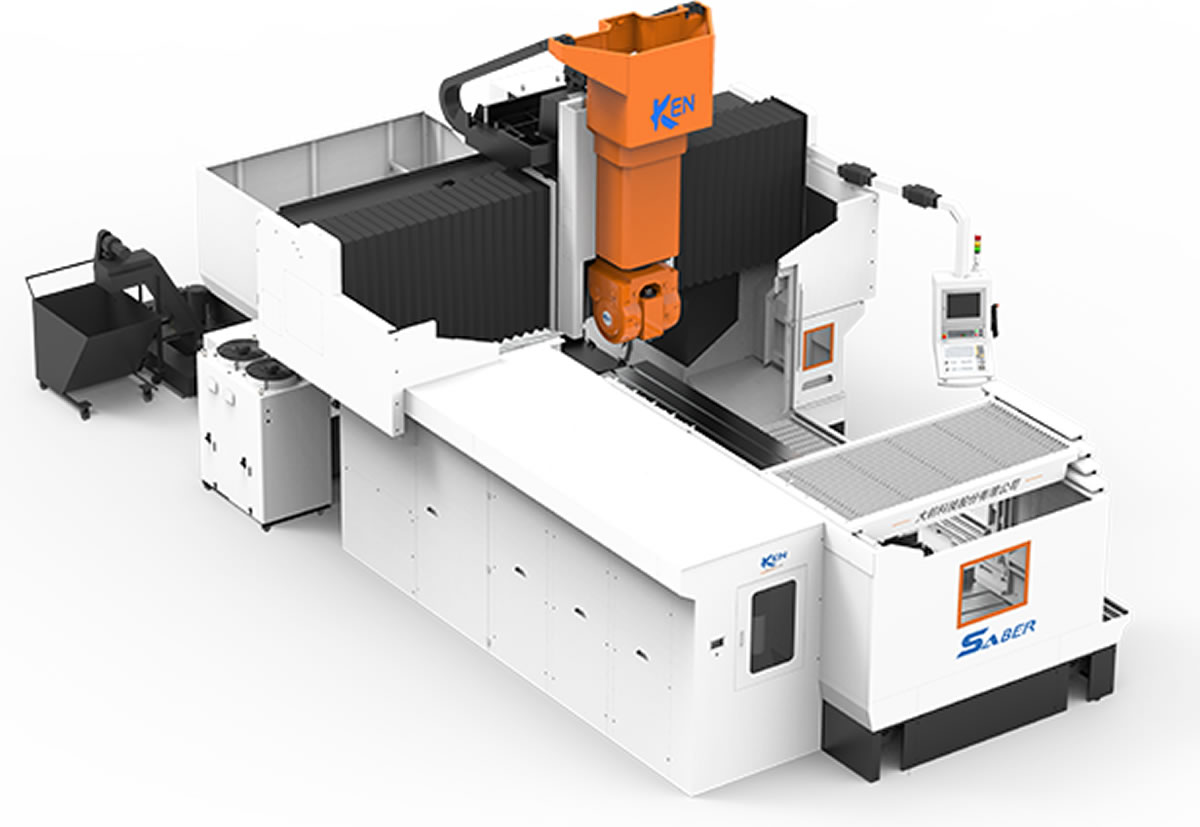

Double Column High Torque 5-Axis Machining Center

- Advanced short column design

- European high-torque mechanical transmission milling head

Features

Z-axis Adopt Box Guideway & Double Hydraulic Cylinder

Achieve The Stability & Excellent Cutting Performance

- Z-axis adopt box guideway design, using double hydraulic cylinder as symmetrical counterweight design,

provide high axial thrust machining,achieve the stability and excellent cutting performance. - Z-axis standard configuration HEIDENHAIN linear scale,

with high feedback accuracy, improve the machining accuracy.

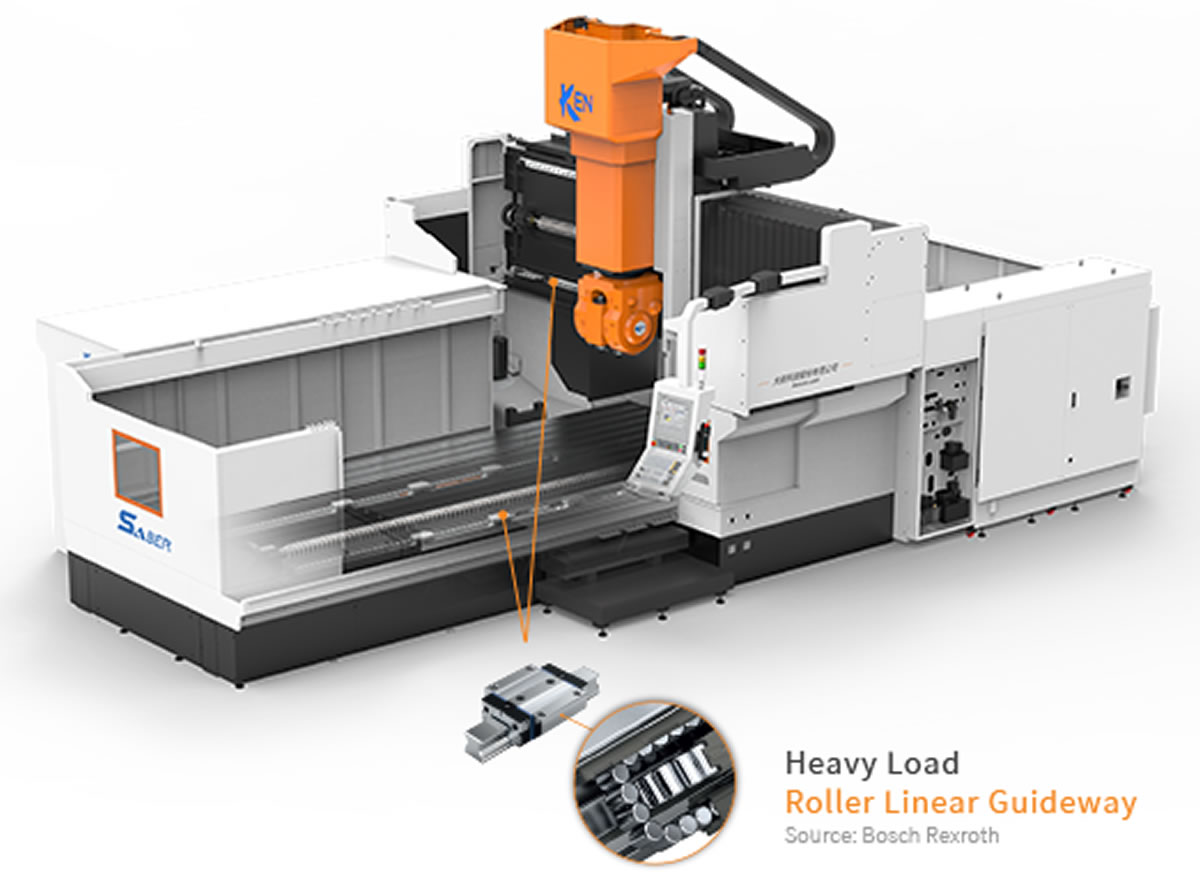

X/Y-Axis Heavy Roller Linear Guideway(Germany)

Achieve High Torque & High Precision

- X-Axis

Saber 24xx/28xx series adopt

2 heavy roller linear guideway,

Saber 35xx series adopt

3 heavy roller linear guideway, with roller linear guide slider, ensure X-axis high rigidity. - Y-Axis

Saber 24xx/28xx/35xx series adopt

2 heavy roller linear guideway. - The high-torque servo motor drives the ball screw through deceleration,

provide high axial thrust and stability during machining, achieve excellent cutting performance.

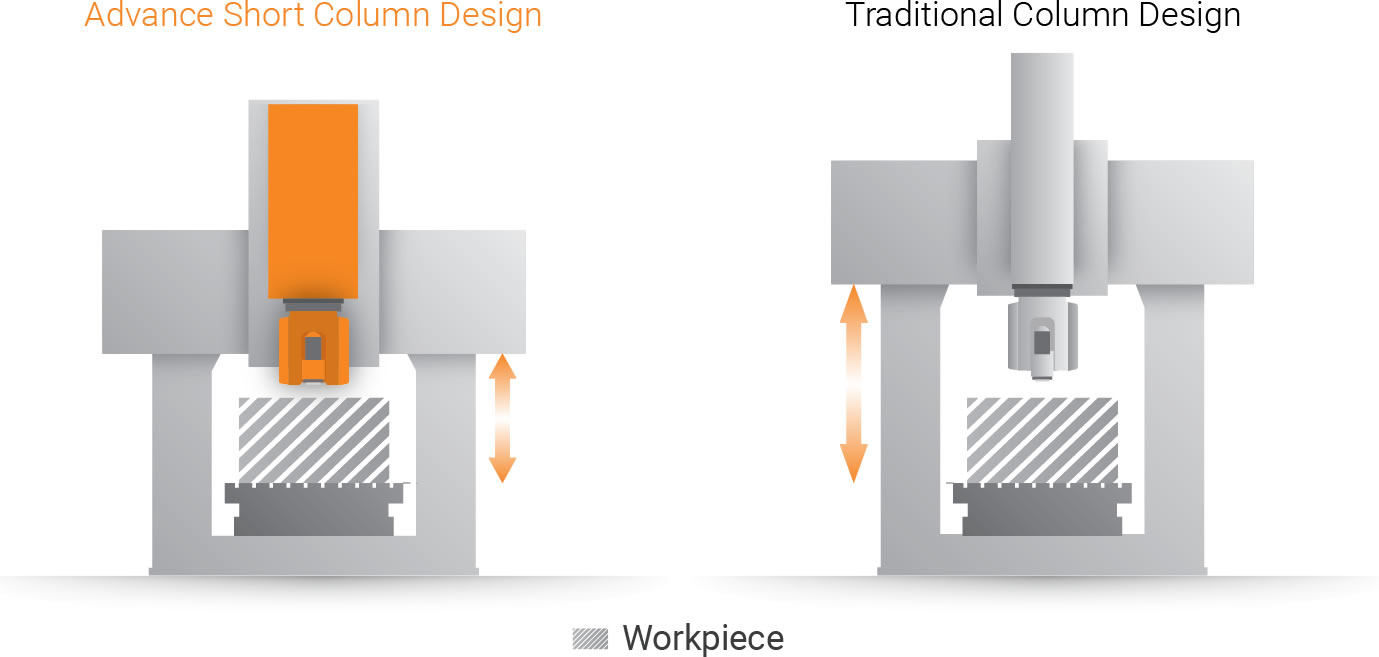

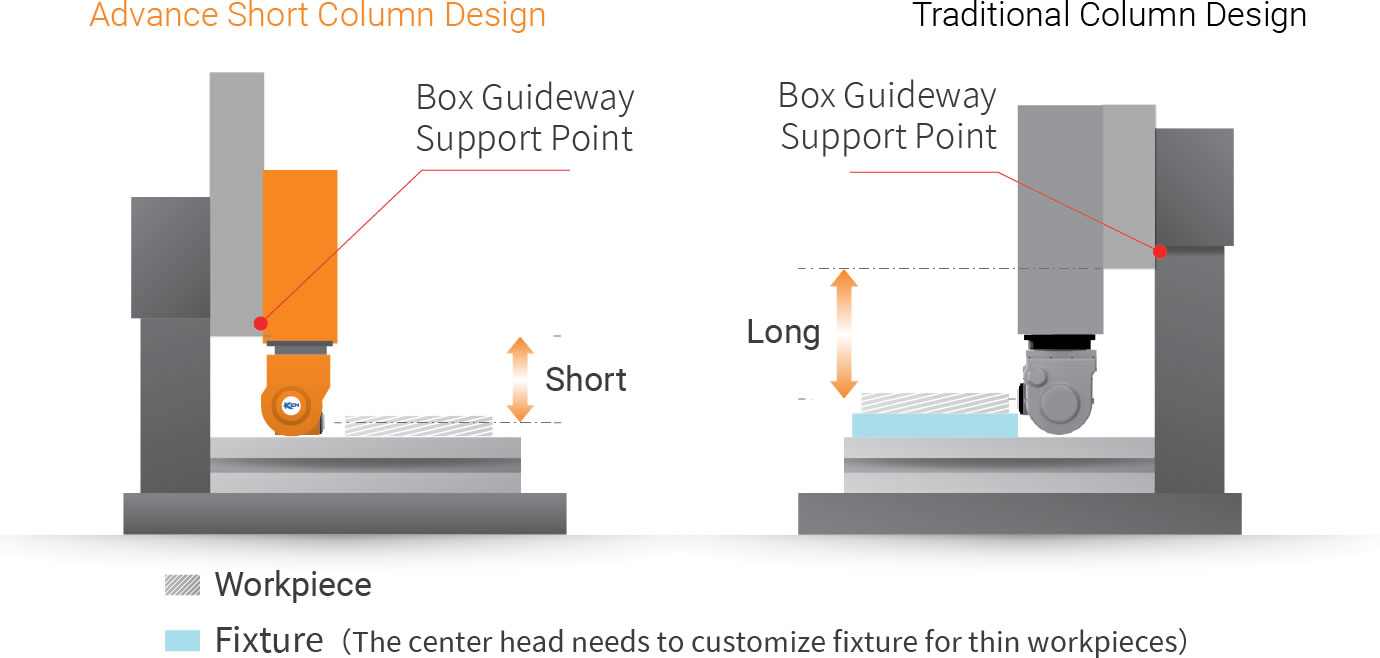

Advance Short Column Structure

The center of gravity of the machine is reduced, the machine rigidity and precision are increased

- Advance short column design minimizes thermal displacement, ensures the best machine rigidity and excellent precision on long-term machining.

- Advance short column design, ensures the rigidity and machine precision when Z-axis is machining at the low point.

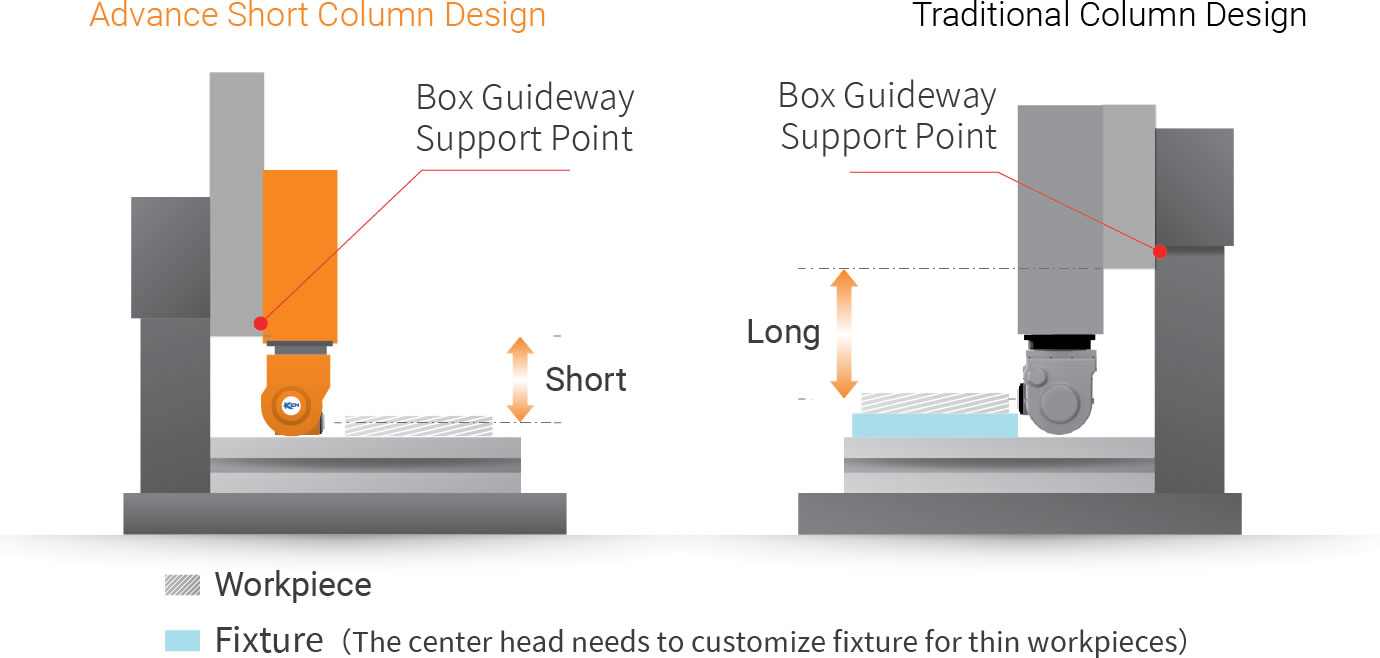

- Advance short column design, the distance between box guideway support point and spindle cutting force point is "short", while Z-axis working at the lowest point still remains high machining rigidity.

- Traditional column design, the distance between box guideway support point and spindle cutting force point is "short", while Z-axis working at the lowest point, the machining rigidity will deteriorate.

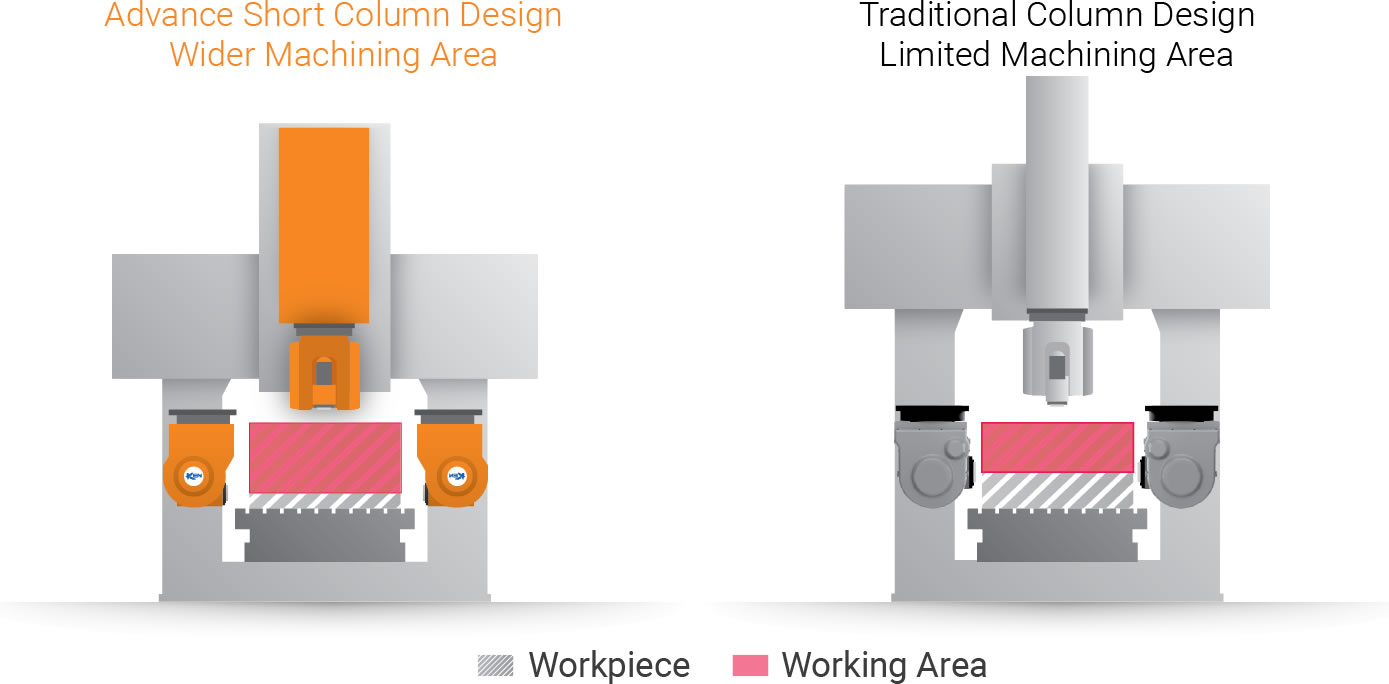

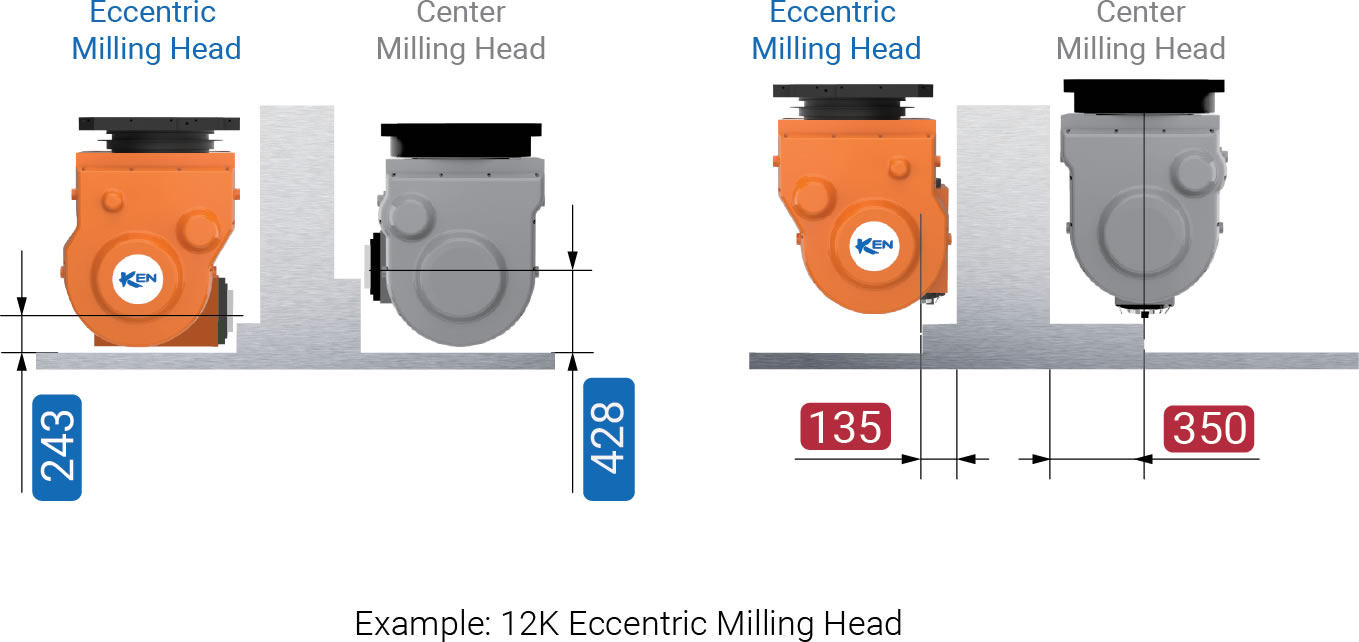

Advance Short Column Structure Adopt Eccentric Milling Head

Posses Wider Machining Area

- Eccentric milling head design, vertical machining possess wider machining area.

- Owing to eccentric milling head design, when A-axis rotate to 90°, the distance between milling head and working table surface is closer, so that the machining area is wider.

- Advance short column design, the distance between box guideway support point and spindle cutting force point is "short", while Z-axis working at the lowest point still remains high machining rigidity.

- Traditional column design, the distance between box guideway support point and spindle cutting force point is "short", while Z-axis working at the lowest point, the machining rigidity will deteriorate.

Specifications

Videos

Milling Head