Gantry Type High Speed 5-Axis Machine Center

- Gantry Type

- Box in Box Symmetrical Design

- High Rigidity U-shpaed Column and Base

- X/Y-Axis Linear Motor Drive

- Feedrate: 60m/min

- Direct-Drive Motor Two-Axis Milling Head

Features

Gantry Type

Gantry type design,all axial components (X/Y/Z/B/C axis) is moving above of the column. The weight of work piece does not affect the machine performance.

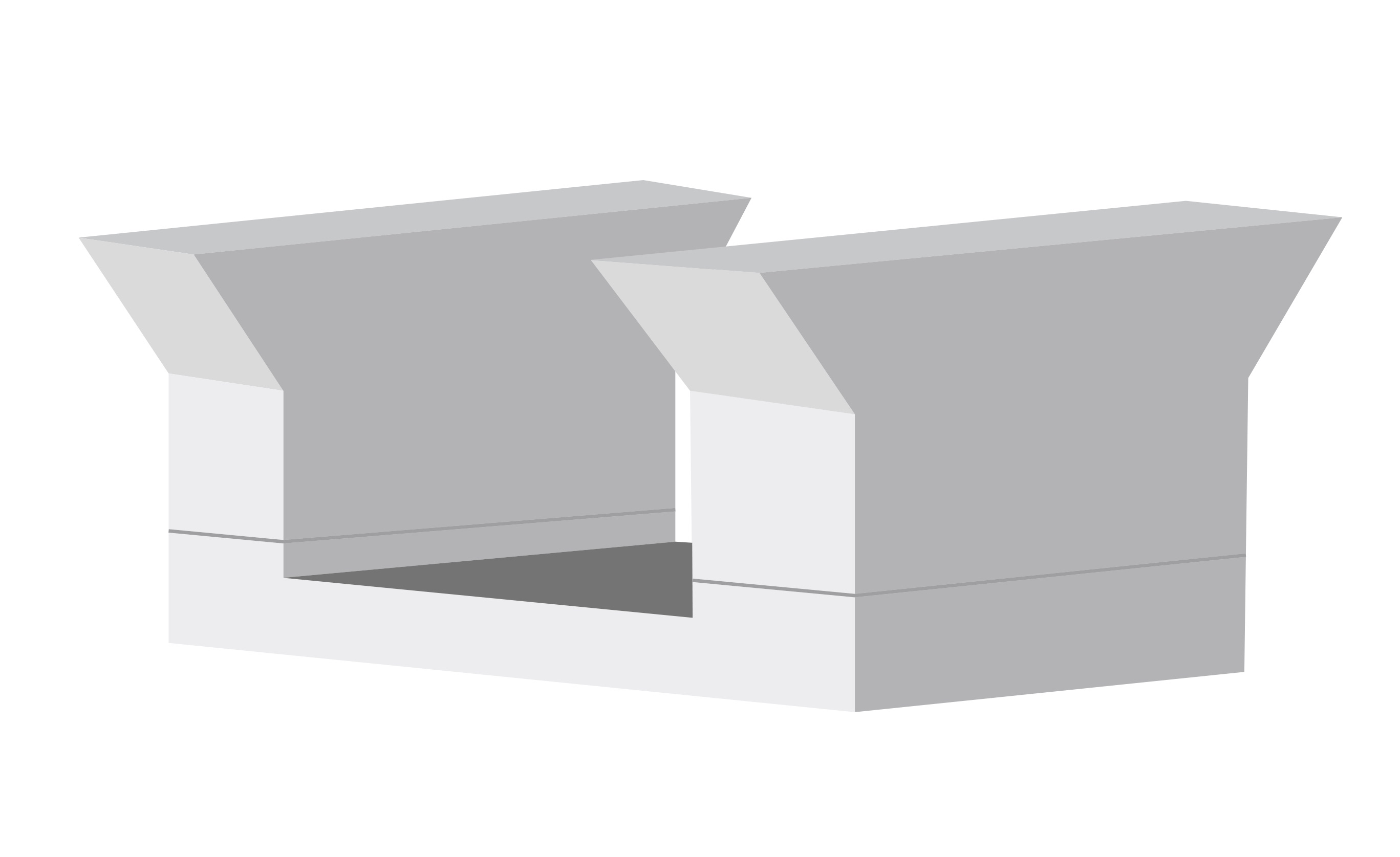

High Rigidity U-shpaed Column and Base

- High rigid U-shaped column and base design

- Improves the overall structural rigidity

- Ensure the stability of precision and

- Precision & Mechanical performance

- Heat deformation

- Minimized even after long period of usage

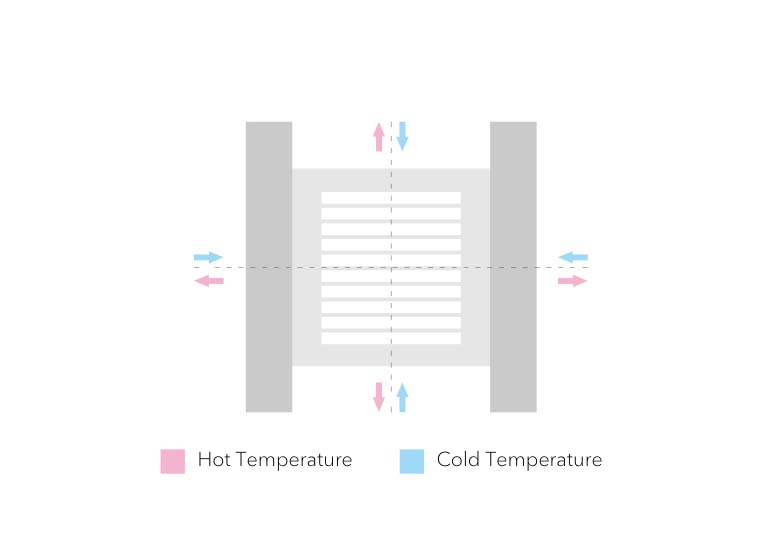

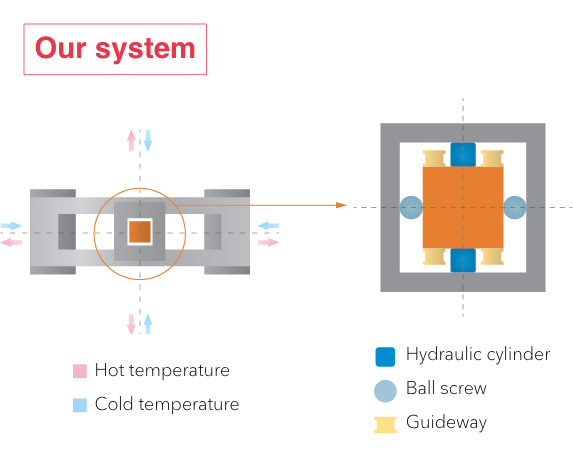

Box-In-Box Symmetrical Design

- Box-in-box design had spindle locating at the center of crossbeam and saddle

- Symmetrical construction makes the machine less susceptible to adverse ambient conditions

- Box-in-box design minimizes thermal displacement and ensures excellent precision during working hours

- Heat deformation will be minimized even after long period of usage

- Y-axis with 4 linear guide ways, the two tracks on XY plan and YZ plan to support Ram & Saddle, which could reach optimize dynamic characteristics

- Z-axis equipped with 4 linear guide ways on two side of the slider, each side undertake the same cutting force, which balance design would enhance the machine lifetime and accuracy

- Dual ball screw and dual counterbalance system in Z axis, its stable structure for high speed cutting purpose

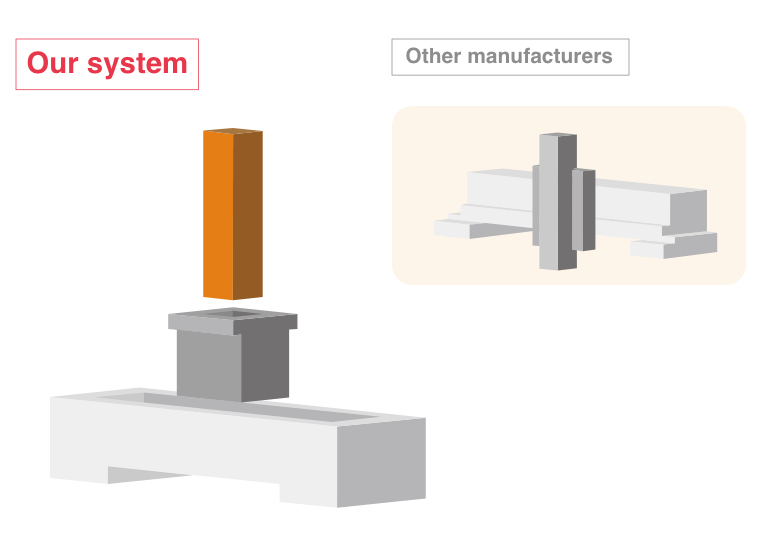

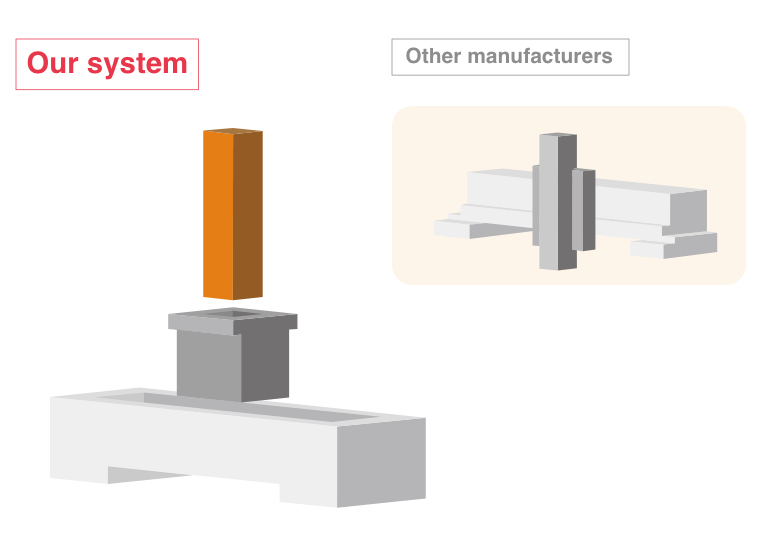

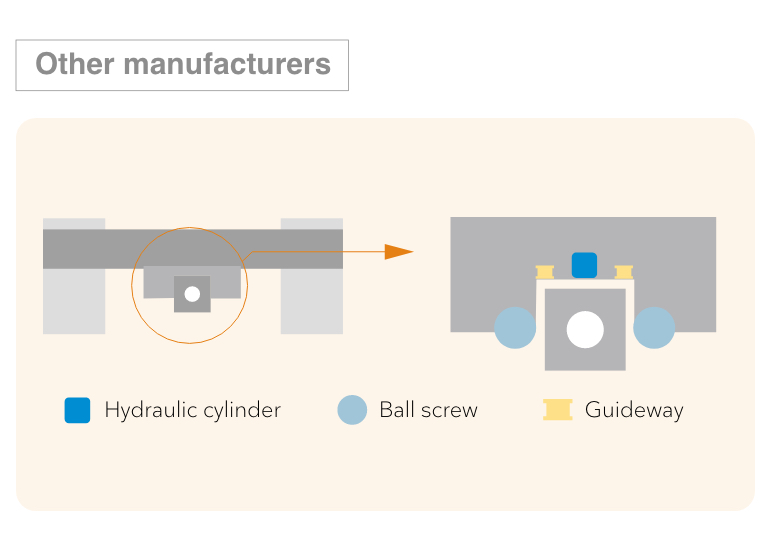

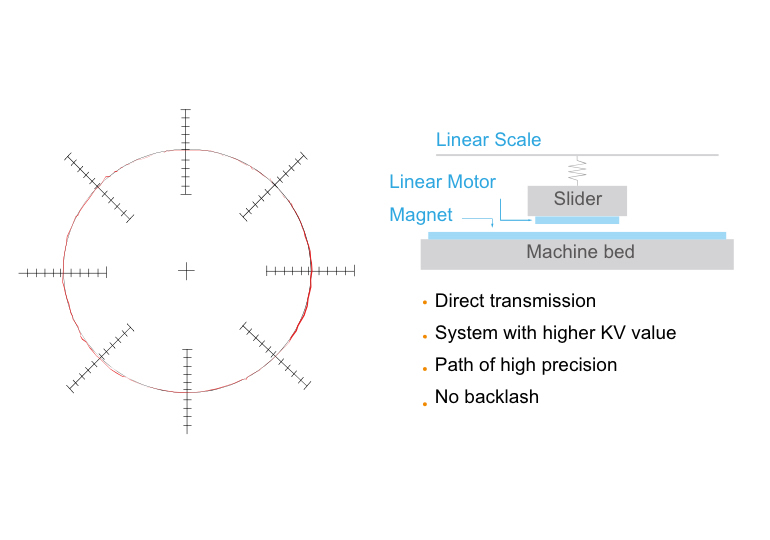

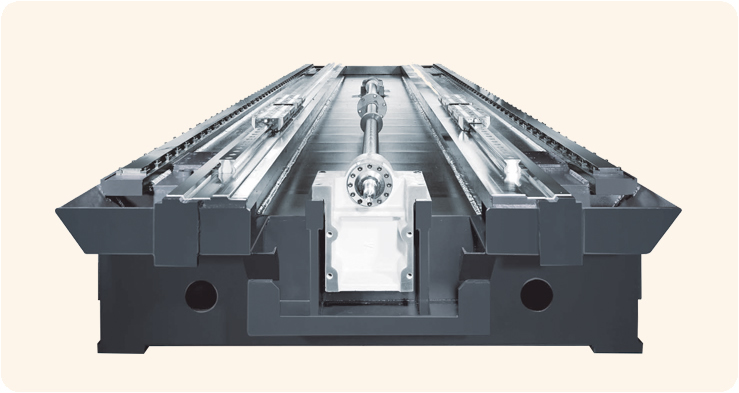

X/Y-Axis Linear Motor Drive

Our System

- From Germany: High speed & high accuracy. Tolerance:0.4 μm

- No backlash, no wear and achieve long lasting accuracy

- High-speed, high-torque, high-acceleration & high-deceleration

- No ball screw, no worn gears, belts can be tired without easy-to-wear transmission mechanism

- Simple structure, fast and convenient maintenance, low maintenance cost

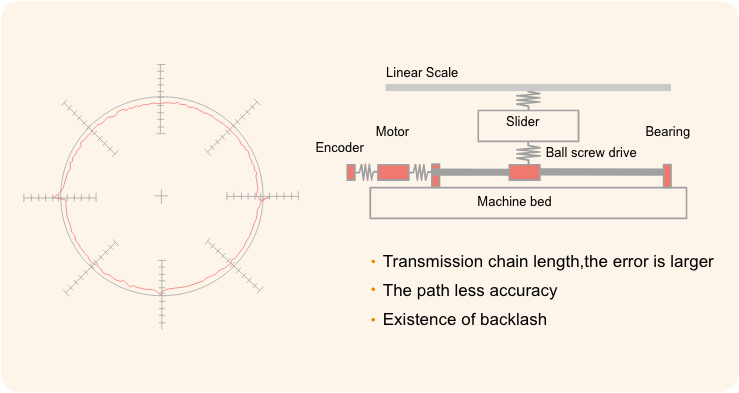

Other Manufacturers

- Tolerance of Ballscrew drive: 5 μm

Milling Head Torque Motor Direct-Drive

- Italian modular design 2-axis milling head, easy maintenance

- Symmetric "open frame" innovative design made in GGG40 modular cast iron for head

- Dedicated "Direct-Drive" torque motor with integrated water cooling system for B/C axis.Free of wear due to friction free drive concept

- Double row crossed roller bearing support achieving excellent rigidity and accuracy for B/C axis

- Using high‐resolution, high‐precision encoder for B/C axis

- Free of wear due to friction free drive concept

Specifications

Videos

Milling Head